Bourdon Sensing Pressure Gauge :

Anandi Instruments offer “MASTER” make Bourdon Sensing pressure gauges. These types of pressure gauges are mainly using in power Generation, food industry, Instrument Manufacturers, Original Equipment Manufacturers, Pharmaceutical, oil Exploration / refineries Petrochemicals, Pulp & Paper, Metallurgy, Cement, Synthetic Fibre, Fertiliser and other Industrial Process Applications.

Specifications :

| Dial Sizes | : | (40mm, 50mm, 63mm, 100mm, 150mm, 250mm) |

| Accuracy | : | ±1% to 2% F.S.D |

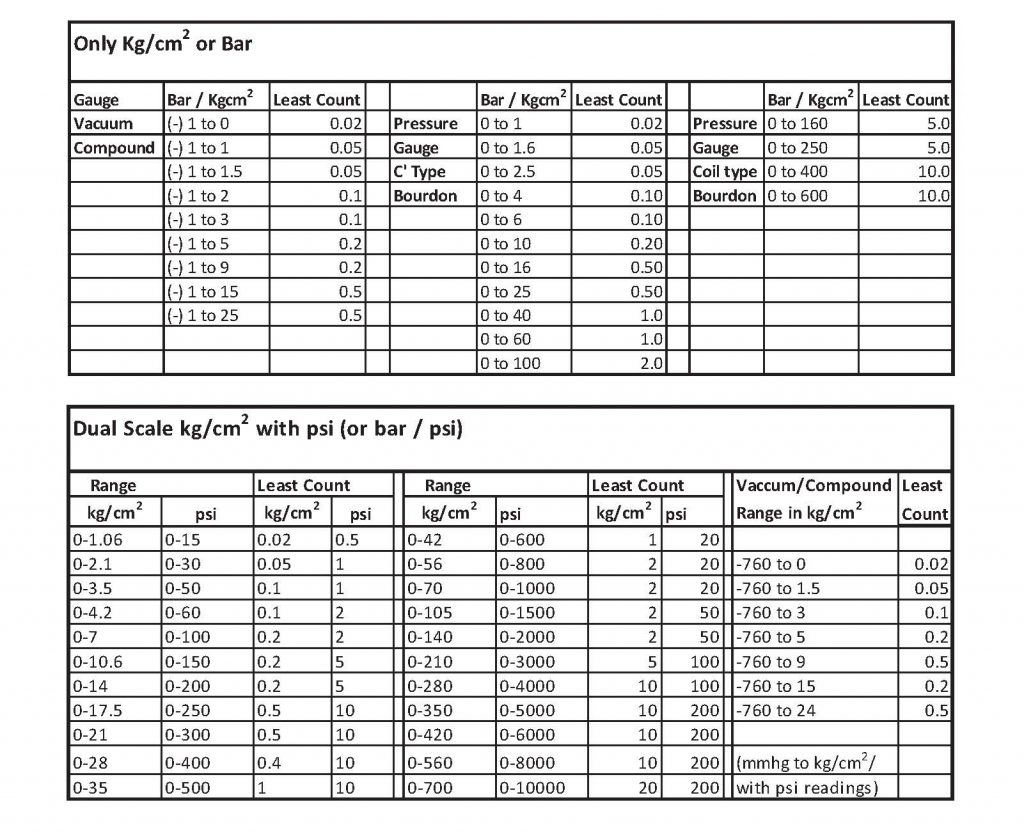

| Ranges | : | Std. Ranges from 0-1 upto 700 bar or kg/cm2 (10000 psi) & Vacuum, Compound Ranges |

| Case & Ring | : | MS Black Coated, SS 304, SS 316 ( Pressed type / Byonet type ) |

| Socket | : | Brass, SS 304, SS 316, SS 316L, Monal, SS 316TI |

| Bourdon Tube | : | Brass, SS 304, SS 316, SS 316L, Monal, SS 316TI |

| : | ‘C’ Shaped Tube upto 70 Bar | |

| : | Coil Shaped Tube Above 70 Bar | |

| Movement | : | SS 304 |

| OverPressure Limit | : | 1.3 times of Full Scale Pressure |

| Joints | : | Arc Argon welded, Solder, Silver Breasing |

| Window | : | Glass |

| Pointer | : | Micro zero adjustable, plain pointer |

| Connections | : | 1/8″, 1/4″, 3/8″, ½” BSP or NPT |

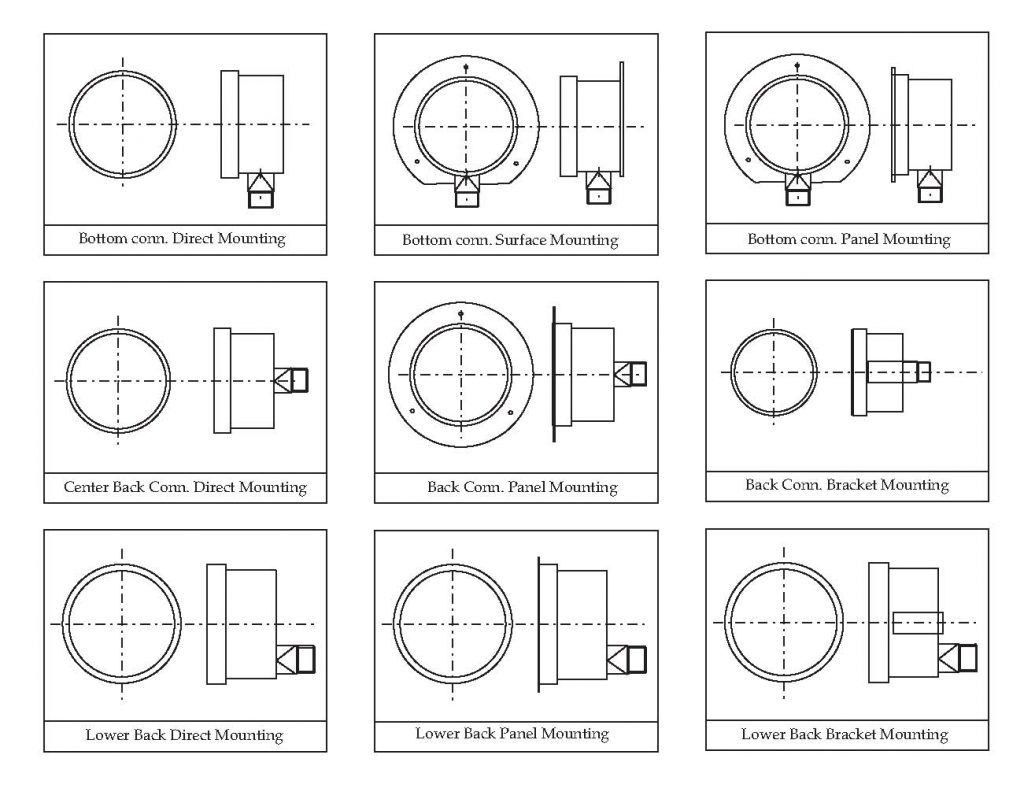

| Mounting | : | Bottom, Bottom Surface, Back, Back Panel, Back Clamp |

| Options Available | : | Glycerin Filling |

| : | Customized Dials – scales, ranges, OEM logos | |

| : | Cleaning for Oxygen Application |

Pressure Range :

Range Selection :

How to Order / Inquire :

Please advise the below

1) dial size

2) connection

3) mounting

4) pressure range

5) application media

6) or any other special requirement